How to Achieve a Smooth Order-to-Cash Process with Process Mining

The order-to-cash process (O2C) is one of those enterprise spanning processes that can either make or break your business. The outcomes of this mission-critical process directly impacts customer satisfaction, how well you manage cash flow, and how happy your employees are.

Yet, the complexity and breadth of the O2C process makes it one of the hardest processes to track and optimize. It’s safe to say that there is a big opportunity for improvements to the O2C process.

In this article, we'll look at how O2C process improvements can be achieved using a strategic combination of process mining and automation.

New to process mining? I recommend you start by reading our introduction to process mining blog post.

Let’s start with the basics of O2C.

What is an order-to-cash process?

The purpose of the O2C process is to deliver goods to a customer in exchange for cash. In a typical sale from stock scenario, the process flow is:

Order creation

Order fulfillment

Order shipping

Invoicing

Payment

These are the core steps in the process, but if you know a bit about the O2C process, you’ll know that it’s never this straightforward! Think of extra steps that make up the process, like post goods issue, creating a delivery, or clearing a credit check. There are millions of transactions that cross departments and systems, making it almost impossible to gain a clear overview of the entire process.

The process consists of two main parts: order management and accounts receivable. And they have slightly different goals.

Order management involves all the steps from order creation to shipping. Order shipping then triggers invoice creation. The goals of order management include improving the perfect order rate, on time shipping rate, and order fulfillment cycle time.

Accounts receivable starts from the moment of invoice creation and ends atinvoice settlement. The goals of accounts receivable include reducing overdue payments and days sales outstanding (DSO).

Challenges

In the O2C process, these two sides (order management and accounts receivable) of the process rely heavily on each other. Order management can’t achieve true efficiency without the support of accounts receivable and vice versa. However, the teams driving these two parts of the process sometimes end up working in silos which does not lend itself to an efficient process.

Other common challenges in the O2C process include:

High error rates due to manual order entry, resulting in costly and time-consuming rework

Poorly maintained customer master data, resulting in delays and lost revenue

Issues with delivery fulfillment, influencing customer retention rates

High DSO rate, impacting cash flow and missed opportunity for investment in other areas of the business.

A complex process like O2C is perfect for using process mining to find automation potential. Without process mining, you’ll only see the tip of the O2C iceberg.

First, use process mining to discover the O2C process

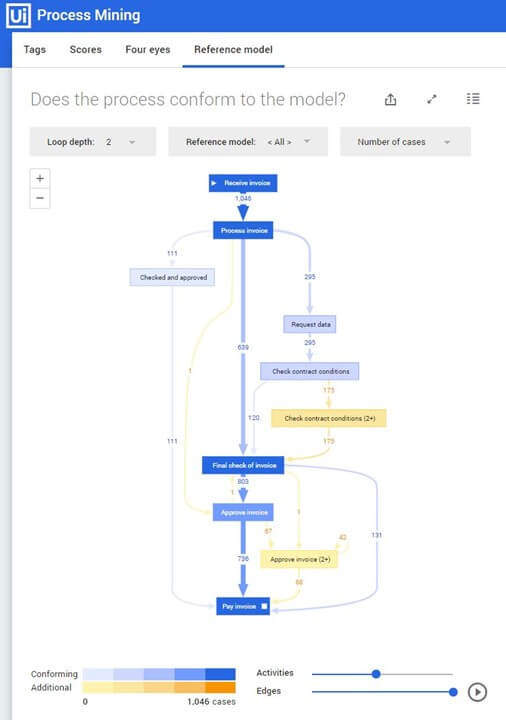

Process mining connects directly to the systems that interface with the O2C process, such as SAP and other enterprise resource planning (ERP) systems. Using an in-built data transformation layer, the technology transforms data into a process graph that chronicles the entire process from start to finish. It captures all process variations, bottlenecks, rework , and exceptions.

Example process graph

With process mining, you can see exactly what happened in the process, figure out why it happened, and work on a plan of action to improve it.

Progress quickly with automation

Process mining guides you in finding the untapped automation potential in your processes. The quickest way to drive transformation in O2C is by deploying robotic process automation (RPA) along with process mining. For example, with process mining, you may discover a post goods issue (i.e. when the order has been picked and is ready for shipping, never happens on time). This may delay delivery to the customer and it also means that incorrect stock levels are shown in the system.

Digging a bit deeper, you find the root cause of this issue is simply that your shipping specialist has too many shipments to handle, which results in a delayed post goods issue. An effective solution for this is having a software robot handle the post goods issue, relieving the shipping specialist of the work and ensuring shipments are delivered on time.

Check out this infographic to find out why process mining is automation’s new superhero.

Continuously monitor and improve the overall process

But process mining doesn’t stop there.

After automating your processes via RPA, you can use process mining to track results and ensure that automation is having the intended effect. It makes sense that after automating, you’d want some insight into the impact on the rest of the process. For example, is the process cycle time improving? Is your on-time shipping rate improving? These are all metrics that can be tracked with process mining, helping you continuously monitor and improve the process.

It may also make sense to optimize your process in other ways, before introducing automation.

For example, one of your customers consistently complains that their shipments arrive later than expected. Using process mining, you can verify that indeed, shipments to this customer always arrive one day later than expected. The root cause in this example is that lead times in the system are one day less than actual lead times, which means there is a discrepancy between the date the customer expects their order and the day they actually receive it. In this example, a simple master data adjustment does the trick and ensures the customer is happy.

Keep processes on track and predictable

As with everything, processes are subject to change. So, it makes sense that your automation changes with it. A combination of process mining and RPA helps you keep tabs on your process so you can act quickly whenever something forces the process to change, whether it’s legislation, competition, or even a pandemic.

Drive O2C improvements with UiPath

Handy capabilities that support keeping your O2C process on track include the ability to assign robots to automatically handle tasks in UiPath Orchestrator, so they can address any unwanted idleness or deviations in near real time. UiPath Action Center ensures the right people are brought into the loop whenever there are some exceptions that need handling.

When you combine process mining with RPA, it can turn into huge leaps in efficiency, cost savings, and customer satisfaction.

UiPath Process Mining combines best-in-class process mining and RPA. As a result, you’re enabled to not only discover automation potential in your O2C process, but also optimize and monitor automation on a continuous basis.

Want to see how leading organizations are using UiPath Process Mining? Find out how Grupo Assa uses process mining and RPA to navigate digital transformation.

Ready to start seeing process mining benefits in your own organization? By using an out-of-the-box UiPath Process Mining connector for SAP O2C, you can get started on improving and automating your O2C process almost immediately. Contact us to get started.

Topics:

Process Mining

Product Marketing Manager, UiPath

Get articles from automation experts in your inbox

SubscribeGet articles from automation experts in your inbox

Sign up today and we'll email you the newest articles every week.

Thank you for subscribing!

Thank you for subscribing! Each week, we'll send the best automation blog posts straight to your inbox.